GenieMat® RST

- Can be installed under all flooring types

- Used to isolate impact footfall and airborne noise

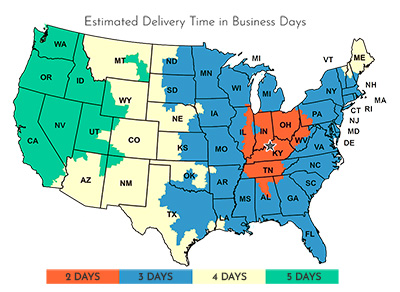

- Lead Time: Ships next day. 2-5 business days for delivery.

View our Product FAQ for answers to common questions about GenieMat® RST products.

An underlayment needs to be resilient and dense to efficiently isolate impact footfall and airborne noise. GenieMat® RST rubber underlayment meets both of these requirements in each available thickness. The thinner GenieMat® RST02 2mm rubber underlayment and GenieMat® RST05 5mm rubber underlayment are recommended when the ceiling below has resilient clips or resilient channel installed. When the ceiling below is fixed to the framing, then the thicker GenieMat® RST10 or GenieMat® RST12 12mm rubber underlayment are recommended. The thicker GenieMat® RST rubber underlayment versions are also recommended when a higher level of performance in isolating impact footfall and airborne noise is required.

GenieMat® RST rubber underlayment has been tested to perform under most common floor finishes including, but not limited to, tile, stone, wood, laminate, vinyl, VCT, and carpet with installation directly to wood, concrete, and steel sub-floors. The GenieMat® RST rubber underlayment has also been tested to meet ANSI standard 118.12 as a crack isolation membrane as well as IAQ test ASTM D5116 for zero VOC.

CONCRETE SUB-FLOOR

Rubber underlayment will always perform best over or under concrete, either full pour or lightweight. Because of the extreme mass and rigidity of the concrete, the rubber is able to compress properly allowing the rubber to add significant resilience to an otherwise rigid structure.

WOOD SUB-FLOOR

Rubber underlayment will not perform over wood sub-floors as predictably as it will over concrete. There are two great ways to mimic the performance of rubber over concrete in a wood structure. The best way is to fix the structural deflection between the joists (read Fixing Structural Deflection). The other way is by layering approximately 7 pounds per square foot of material over the sub-floor or over the GenieMat® RST. Layering directly to the sub-floor will help more with low frequency airborne and footfall impact noise transfer while layering over the GenieMat® RST will increase the STC rating by at least a couple points with a slight reduction in low frequency performance. Any heavy material will work for layering, e.g. plywood, OSB, MDF, drywall, 3/4" lightweight concrete, or a cementitious board like HardiBacker. Layering several pounds per square foot of material over the GenieMat® RST is not required, but recommended in order to maximize the performance of the rubber underlayment in a wood structure.

Layering also provides an opportunity to add more damping to the floor with a product like our Green Glue Compound. Including Green Glue Compound will add to the isolation of both impact footfall and airborne noise. Decoupling the ceiling below with GenieClips or resilient channel increases the value of the GenieMat® RST in both concrete and wood structures. The highest rated floor/ceiling assemblies will have resilience in both the floor and the ceiling.

Read our article Maximizing Rubber Underlayment Performance for more detailed information.

If the joists below can be stiffened using stepped blocking, then layering can be avoided. Read our article Fixing Structural Deflection for more detailed information.

GenieMat® RST is only available in one size of roll per thickness. Partial or larger rolls cannot be purchased. Overestimating by 5% provides enough material for most projects. We suggest drawing the room dimensions and planning the installation layout to determine the appropriate number of rolls for the project.

| GenieMat® RST Sizes | ||||

|---|---|---|---|---|

| Style | Dimensions | Coverage | Thickness | Roll Weight |

| GenieMat® RST02 | 4' x 75' | 300 square feet | 1/8" (2mm) | 125 pounds |

| GenieMat® RST05 | 4' x 30' | 120 square feet | 1/4" (5mm) | 120 pounds |

| GenieMat® RST10 | 4' x 15' | 60 square feet | 3/8" (10mm) | 125 pounds |

| GenieMat® RST12 | 4' x 13' | 52 square feet | 1/2" (12mm) | 130 pounds |

| GenieMat® RST15 | 4' x 15' | 60 square feet | 5/8" (15mm) | 190 pounds |

GenieMat® RST Simple Installation Manual PDF 173 KB

GenieMat® RST Technical Installation ManualPDF 329 KB

The GenieMat® RST can be cut with a standard razor knife. The rubber can have an odor to it when it first arrives. This smell typically fades away similarly to a newly painted room. If the smell lingers or the user is sensitive to the smell of rubber, cover the rubber with a 4-mil plastic sheeting.

INSTALLATION FOR FLOATING FINISHED FLOOR INSTALL

Follow these steps if installing a floating hardwood or laminate, nailed down hardwood, or carpet over the GenieMat® RST.

- Roll out the material and cut to fit, leaving up to a 1/4" gap on the perimeter.

- Butt the seams together, avoid overlapping.

- Cover seams with standard duct tape. Fill in gaps with acoustical sealant before taping.

- Install flooring directly to the GenieMat® RST or to the additional layering over the GenieMat® RST if applicable.

INSTALLATION FOR FIXED FINISHED FLOOR INSTALL

When using grouted or fully adhered flooring materials, the GenieMat® RST must be adhered to the sub-floor with a suitable adhesive. The finished floor can then be installed directly to the GenieMat® RST.

- Use a 1/16" notched trowel to apply a urethane based adhesive to the sub-floor.

- Carefully lay the GenieMat® RST into the wet adhesive to avoid wrinkles or air pockets. A 40+ pound roller is recommended for adhering the thinner RST-02 or RST-05.

- Cut the GenieMat® RST to fit, leaving up to a 1/4" gap on the perimeter.

- Continue with the next row, butt the seams together, avoid overlapping. Complete each row before moving to the next.

- Cover seams with standard duct tape. Fill gaps with acoustical sealant before taping.

- Install flooring directly to the GenieMat® RST or to the additional layering over the GenieMat® RST if applicable.

| GenieMat® RST Specs | |

|---|---|

| R-Value | (R-.1) Almost zero, safe for use above or below radiant heat |

| Fire Rating | Dependent on rating of finish floor |

| Composition | 94% recycled rubber |

| Installation | Free floating, urethane adhesive, or thinset |

| TCNA Robinson Test | Extra heavy commercial for GenieMat® RST02, moderate commercial for GenieMat® RST05, light commercial for other GenieMat® RST |

| Health Rating | Zero VOC, healthy and environmentally friendly |

| LEED Points | Adds up to 10 LEED points |

| Mold Growth | Impermeable to water and inhibits growth of mold |

| GenieMat® RST Downloads | |

|---|---|

| GenieMat® RST02 Product Specs | DownloadPDF 231 KB |

| GenieMat® RST05 Product Specs | DownloadPDF 216 KB |

| GenieMat® RST10 Product Specs | DownloadPDF 216 KB |

| GenieMat® RST12 Product Specs | DownloadPDF 210 KB |

| GenieMat® RST15 Product Specs | DownloadPDF 213 KB |

| GenieMat® RST Product Brochure | DownloadPDF 1.7 MB |

| Pliteq Floor/Ceiling Ratings | DownloadPDF 512 KB |

| GenieMat® RST Simple Installation Manual | DownloadPDF 172 KB |

| GenieMat® RST Technical Installation Manual | DownloadPDF 329 KB |

| GenieMat® RST Technical Installation Manual For Vinyl Floor Coverings | DownloadPDF 306 KB |

| GenieMat® RST 3-Part Guide Spec | DownloadPDF 312 KB |

*All test results shown in this table were achieved through third party testing from accredited laboratories. The full test is available upon request.

| Independent Sound Test Results | |||

|---|---|---|---|

| Structure | Assembly | STC | IIC |

| Concrete | 8" concrete, no ceiling, RST02, hardwood | 58 | 54 |

| Concrete | 8" concrete, no ceiling, RST02, tile | 58 | 48 |

| Concrete | 8" concrete, no ceiling, RST05, vinyl plank | 58 | 55 |

| Concrete | 8" concrete, no ceiling, RST05, hardwood | 58 | 56 |

| Concrete | 8" concrete, no ceiling, RST05, tile | 58 | 50 |

| Concrete | 8" concrete, no ceiling, RST10, vinyl plank | 58 | 56 |

| Concrete | 8" concrete, no ceiling, RST10, hardwood | 58 | 56 |

| Concrete | 8" concrete, no ceiling, RST10, tile | 58 | 53 |

| Concrete | 8" concrete, no ceiling, RST12, tile | 59 | 55 |

| Wood | Wood joists, R-19 insulation, no flooring, single 5/8" drywall ceiling | 43 | 32 |

| Wood | Wood joists, R-19 insulation, vinyl, double 5/8" drywall on GenieClip® RST | 54 | 51 |

| Wood | Wood joists, R-19 insulation, RST02, carpet, double 5/8" drywall on GenieClip® RST | 53 | 58 |

| Wood | Wood joists, R-19 insulation, RST02, hardwood, double 5/8" drywall on GenieClip® RST | 54 | 56 |

| Wood | Wood joists, R-19 insulation, RST02, tile, double 5/8" drywall on GenieClip® RST | 54 | 57 |