TotalMass MLV Barrier

- Best used in areas where decoupling or damping cannot be used

- Ideal for windows, doors, fences, pipes, and similar uses

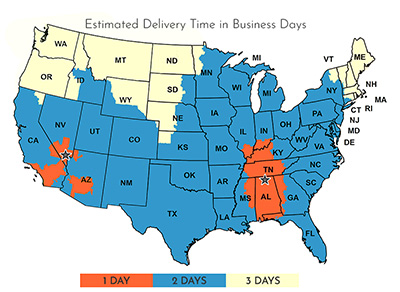

- In stock and shipping daily from east and west coast for quick delivery

View our Product FAQ for answers to common questions about TotalMass MLV.

Mass loaded vinyl (MLV) is one of the original sound control products. For some time, it was considered the best solution for effective sound reduction. With advances in technology, higher-rated products have been introduced, providing more cost effective alternatives in walls, ceilings, and floors. However, TotalMass MLV Barrier still has its place in sound isolation. One big advantage to MLV is that it works essentially anywhere. It doesn't rely on an assembly with particular spacing for framing, or common walls, or existing drywall, or certain finish floors, etc. MLV is an acoustically dead material that will bring a value, sometimes big and sometimes small, to any assembly.

The largest gains are experienced in walls, doors, windows, and other odd areas like around pipes, duct work, in curtains, in cars, and hanging on exterior fences.

Looking for seam tape?

If your project requires the use of seam tape, then we recommend using Everbilt Seam Tape to adhere best to our mass loaded vinyl. This tape is UV stable and sticks in both hot and cold weather. A quick search online and you will find numerous suppliers.

1 LB VS. 2 LB vs. 1/2 LB

The standalone STC rating of each of these thicknesses/weights jumps about 5 points as the material thickness increases (STC 22, STC 27, STC 32). Although a 5 STC point difference is generally a doubling effect to the human ear, the actual gains can be more significant, or less significant, depending on the exact frequency. So in real world terms, we recommend considering each product this way: The 1/2 LB is best utilized with higher frequency sound issues and in curtains or other areas that require extra flexibility, the 1 LB is a little more balanced between upper low frequencies to higher frequencies and more universally used, and the 2 LB is best in the lower range to upper mid range frequencies. Also, the 5 point difference is only fully realized when the material is installed as a standalone product and not in a wall or ceiling assembly. In a wall or ceiling you should expect less of a difference overall from one thickness to another. The difference is testable though and noticeable.

WALLS

Installing TotalMass Mass Loaded Vinyl Barrier in a standard duty wall will decrease sound transmission. These gains are the result of resolving resonance issues in common building materials and not the mass of the material as it weighs less per square foot than a layer of drywall. The most significant gains are in the mid to high frequency ranges. Offices, bedrooms, and any area with sound issues relating to voices and television noise will benefit from TotalMass MLV. A standard duty wall, (2x4 framing, single layer drywall on each side, and insulated stud cavities) will achieve an approximate STC 45 with 1 LB TotalMass and an approximate STC 48 with 2 LB TotalMass. Which is a very noticeable jump over a standard wall and accomplished without any demo or decoupling.

CEILINGS/FLOORS

Basic ceiling and floor assemblies already consist of a variety of materials with different resonating properties. Because of this, the benefit of TotalMass in a ceiling or floor is often less significant. The use of mass loaded vinyl barrier in a non-resilient ceiling/floor assembly (an assembly with no resilient clips or channel installed) can provide a slight improvement in airborne noise isolation only. If the sub-floor is concrete or lightweight concrete, MLV will have no value in the assembly. TotalMass MLV will not help to improve impact footfall performance in either wood or concrete assemblies. For significant gains in ceilings, we recommend the GenieClip and for floors, GenieMat RST rubber underlayment.

ACOUSTIC GRID BLANKET

A frequent complaint in commercial office space is sound transfer from over the top of common walls, or the floor above, coming through the acoustic grid ceiling. Without converting the acoustic grid ceiling to a framed assembly with drywall, the best option is to add a layer of MLV atop the acoustic grid panels. Click the installation tab to view more on installing mass loaded vinyl sound barriers on acoustic grids.

DOORS/WINDOWS

Using mass loaded vinyl as sound dampening curtains over doors and windows is a great use for the material (1/2 LB is most common in this application). Mass loaded vinyl curtains provide a decent amount of mass without permanently blocking the opening. Click the installation tab to view more on installing over doors and windows.

WALLS/CEILINGS

TotalMass MLV can be fastened using nails, screws, or staples. When fastening with nails or screws, it is advisable to use a thin washer to distribute the weight of the material and avoid tearing the material. We recommend hanging MLV parallel with the framing to avoid awkward overlapping seams. Seams can be taped together using standard duct or foil tape between the framing members or on the stud/joist as long as you keep the seam tight. If you join the seams over the framing, we recommend applying acoustical sealant over the seam before taping. Special attention is required around openings such as electrical, duct, and plumbing. Acoustical sealant or caulking and tape is recommended to keep the seal around these openings tight.

View Wall and Ceiling MLV Install Guide

FLOORS

A floating floor installation is recommended for maximum sound isolation benefits. Roll out the MLV, butt the seams tight, tape to hold the seams in place, and seal any gaps with acoustical sealant. The finished floor or additional layers of mass can be installed directly over the MLV. We do not recommend installing tile or other sensitive floor finishes directly on the MLV. For impact footfall isolation, use GenieMat RST instead of TotalMass MLV.

ACOUSTIC GRID CEILINGS

Cut pieces of MLV slightly wider and longer than each panel, overlapping other pieces to cover the grid track. Pieces can be glued onto each panel or laid loosely atop the acoustic panels.

DOORS/WINDOWS

Cutting a piece of vinyl to fit over your door(s) or window(s) with grommets on each corner for hanging will provide you with an easy temporary solution for these openings. Grommets can be purchased from any local hardware store.

PIPES/DUCT WORK

The goal of wrapping pipes and ducts is to minimize surface vibration resonance. Installation is simple by cutting the MLV to fit, overlapping slightly, and taping the seam with a basic duct or foil tape. Both tape products can be purchased from any local hardware store.

| TotalMass MLV Barrier Downloads | |

|---|---|

| TotalMass 1 LB, 2 LB, and 1/2 LB Product Specs | DownloadPDF 420 KB |

| TotalMass Sell Sheet | DownloadPDF 667 KB |

| TotalMass MLV Barrier MSDS | DownloadPDF 80 KB |

| TotalMass 1 LB Specs | |

|---|---|

| Dimensions | 4' x 25' (100 square feet) or 4' x 10' (40 square feet) |

| Thickness | 1/8" (2.6mm) |

| Weight | 102 pounds or 42 pounds |

| Color | Black |

| Tensile Strength | 143.9 psi |

| STC Rating | 27 |

| UL Certification | Flammability rating MVSS 302. UL/reinforced versions available with minimum order of 360 linear feet. |

| TotalMass 2 LB Specs | |

|---|---|

| Dimensions | 4' x 15' (60 square feet) |

| Thickness | 1/4" (5mm) |

| Weight | 122 pounds |

| Color | Black |

| Tensile Strength | 143.9 psi |

| STC Rating | 32 |

| UL Certification | Flammability rating MVSS 302. UL/reinforced versions available with minimum order of 360 linear feet. |

| TotalMass 1/2 LB Specs | |

|---|---|

| Dimensions | 4' x 25' (100 square feet) |

| Thickness | 1/16" (1.2mm) |

| Weight | 52 pounds |

| Color | Black |

| Tensile Strength | 143.9 psi |

| STC Rating | 22 |

| UL Certification | Flammability rating MVSS 302. UL/reinforced versions available with minimum order of 360 linear feet. |

Mass loaded vinyl tests show little to no gain when included in assemblies using resilient clips or resilient channel. The gains achieved in basic walls, floors, and ceilings are created by resolving resonance issues and not from the actual mass of the vinyl. The standalone rating is only relevant when the material is exposed, i.e. around pipes, duct, hung from fences, in curtains over windows or doors, etc.

*All test results shown in this table were achieved through third party testing from accredited laboratories. The full test is available upon request.

| Independent Sound Test Results | ||||

|---|---|---|---|---|

| Type | Assembly | STC | OITC | IIC |

| Ceiling | Not tested in any ceiling assembly | - | - | - |

| Wall | Wood studs, R-13 insulation, two 5/8" drywall total | 37 | 28 | - |

| Wall | Wood studs, R-13 insulation, two 5/8" drywall total with 1 LB to studs | 45 | 28 | - |

| Standalone | TotalMass 1 LB | 26/27 | - | - |

| Standalone | TotalMass 2 LB | 31/32 | - | - |

| Performance by Frequency | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Weight | 100 Hz |

125 Hz |

160 Hz |

200 Hz |

250 Hz |

315 Hz |

400 Hz |

500 Hz |

630 Hz |

800 Hz |

1,000 Hz |

1,250 Hz |

1,600 Hz |

2,000 Hz |

2,500 Hz |

3,150 Hz |

4,000 Hz |

5,000 Hz |

||||||

| 1 LB | 21 | 17 | 15 | 16 | 17 | 19 | 20 | 23 | 25 | 26 | 28 | 29 | 30 | 33 | 34 | 35 | 37 | 39 | ||||||

| 2 LB | 26 | 22 | 21 | 22 | 23 | 25 | 26 | 28 | 30 | 31 | 33 | 34 | 36 | 38 | 40 | 41 | 43 | 45 | ||||||