Acoustic Sleeper

- Low profile solution for decoupling floors, stages, and risers.

- STC, IIC, UL, and structural tests to prove efficacy. Better performance and proven performance, unlike joist isolators or similar solutions.

- Low Shore A durometer is soft enough to allow performance in both concrete and wood structures.

- Ship daily from our Georgia inventory. Delivery 7 days a week to residential addresses.

The Acoustic Sleeper is a high performance solution for decoupling floors, stages, risers, and other similar assemblies over wood or concrete structures. Each Acoustic Sleeper is only 1/4" thick, resulting in an addition of just 1-1/8" overall to the assembly thickness when combined with the required double layer 1/2" OSB.

WHY OTHER SOLUTIONS GENERALLY DON'T WORK

Other competing solutions like u-channel joist isolators and waffle pads require a high durometer for manufacturing purposes. Products with a high durometer require more pressure to deflect (compress), or in other words, require more pressure to actually work. If installed correctly, this makes for a very thick floor at a high cost per square foot. If installed incorrectly (most common result), this makes for a floor with not much value in terms of soundproofing. A concrete substrate is required to provide mass and rigidity for other solutions to isolate any sound, and even then the performance would be limited because of the stiffness of the rubber. If you are attempting to isolate the floor of a wood structure, then significant mass would need to be added above or below the system. So much mass that the structure likely would not be able to support it, or so much mass and thickness that most customers would not be willing to make the appropriate accommodations because of cost and the height required. A proper installation of u-channel joist isolator systems require a buildup of at least 6", making for an unusually thick floor with, at best, minimal performance gains.

The typical end result for other competing solutions is a decoupled floor for the sake of claiming a decoupled floor. The real world gains expected are not ultimately achieved. There are not STC, IIC, UL, or structural tests for these solutions. They are generally solutions promoted by companies online or in online forums as a 'better than nothing' approach with a huge question mark on what they are really accomplishing.

WHY ACOUSTIC SLEEPERS DO WORK

- The Acoustic Sleeper is manufactured with a low Shore A durometer of 40, putting it in line with resilient clips with the softest rubber base. This allows for full deflection with minimal added mass and is an ideal softness for low frequency attenuation.

- The design of the Acoustic Sleeper is such that only the two outside edges make contact with the floor. As opposed to other solutions, like u-channel joist isolators, that make full contact with the floor, or waffle pads, that make nearly full contact with the floor. With the Acoustic Sleeper, 99.8% of the calculated floor area is isolated from the structure.

- Low profile 1/4" Acoustic Sleeper plus double layer 1/2" OSB stackup fits with most assemblies without a significant step-up to the newly decoupled floor. Meaning this solution generally works on all floors, even in retrofit applications.

Whether the structure is concrete or wood, simply attach the Acoustic Sleepers to the back of a 1/2" OSB panel per the installation instructions, flip it over, fasten another 1/2" layer on top, and you're installed.

This simple assembly is independently tested in both concrete and wood structures to show significant gains in isolation. An improvement of 24 IIC points in a basic 6" concrete structure and gains of 5 STC and 5 IIC points in wood structures. These tests are in simple assemblies comparing a base assembly to an assembly that has only the Acoustic Sleeper and T&G OSB added on top.

Based on our experience and results from customers, a safe estimate is square footage divided by 2 to find the number of Acoustic Sleepers needed for your project.

Example: With standard Sleeper spacing, a 1,000 square foot floor would require 500 pads (1,000 square feet / 2 = 500).

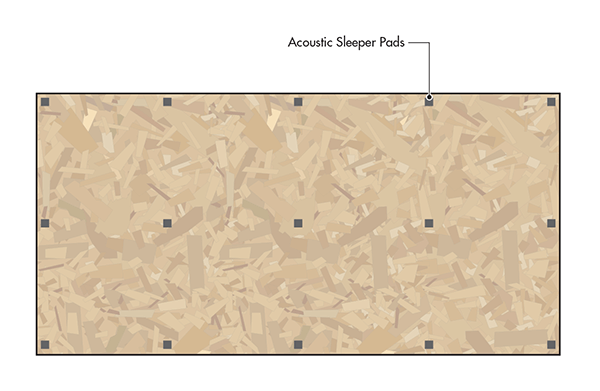

The drawing below represents a 4' x 8' sheet of OSB showing the Acoustic Sleeper spaced 24" on center along the perimeter and in the field.

| Quick Estimate On Various Panel Sizes | ||||

|---|---|---|---|---|

| 4' x 8' | 15 Acoustic Sleepers | |||

| 4' x 7' | 15 Acoustic Sleepers | |||

| 4' x 6' | 12 Acoustic Sleepers | |||

| 4' x 5' | 12 Acoustic Sleepers | |||

| 4' x 4' | 9 Acoustic Sleepers | |||

| 4' x 3' | 9 Acoustic Sleepers | |||

| 4' x 2' | 6 Acoustic Sleepers | |||

| 4' x 1' | 6 Acoustic Sleepers | |||

The Acoustic Sleeper is fastened to the bottom side of a sheet of 1/2" OSB following a basic spacing pattern as shown below. The Sleepers do NOT fasten or glue to the sub-floor below. The pads are spaced in rows 24" on center with rows also spaced 24" apart. Each panel should be treated independently from the next panel. The Acoustic Sleeper is 1/4" thick and can be fastened using standard 3/4" screws or nails, as well as wide crown staples, or even urethane adhesive. Once the first layer is completed, flip over the plywood to sandwich the Sleepers between the sub-floor and the first layer of plywood. Then fasten a second layer of 1/2" cross plied to the first layer. Seal the perimeter of the floor with acoustical sealant and install any type of flooring over the top. Floating floors and nailed down floors recommended.

![]()

TRIPLE LEAF: Decoupling over an existing substrate in an assembly with a drywall ceiling below will create resonance issues known as a triple leaf effect. Reduce this resonance by including Green Glue Compound or TotalMass MLV Barrier between the two layers of plywood.

![]()

BUILDING WALLS ON TOP OF SLEEPERS: To build walls on top of a decoupled Acoustic Sleeper floor, use a 1/4" thick plywood cut in 4" strips in place of the perimeter Acoustic Sleepers. The perimeter walls would be built on top of the 4" strips only.

![]()

| Acoustic Sleeper Specs | |

|---|---|

| Coverage | Estimated 1 pad for every .5 square feet (15 per 4' x 8' sheet) |

| Dimensions | 1-1/2" square x 1/4" thick for the pad. |

| Material | Rubber with Shore A durometer of 40 |

| UL Ratings |

Wood joists: 1 hour, L502, L506, L514. 2 hour L505. I-Joists: 1 hour, L589. Wood Truss: 1 hour, L528, L563, L574. 2 hour L577. Metal Joists: 1 hour, L524. Light Gauge Metal Truss: 1 hour, L560, L565. |

| Spacing | Standard spacing 24" within each row with rows spaced 24" apart. |

| Fasteners | Use 1/2" nails, screws, or wide crown staples, or general urethane adhesive to fasten the Sleeper to the bottom of the first layer of 1/2" OSB. |

| Acoustic Sleeper Downloads | |

|---|---|

| Acoustic Sleeper Product Data and Submittal Sheet | DownloadPDF 902 KB |

| Comprehensive Product Guide | DownloadPDF 5.74 MB |

| Concrete Assembly Info | DownloadPDF 412 KB |

| Wood Assembly Info | DownloadPDF 450 KB |

| Acoustic Sleeper Application Drawings | DownloadPDF 757 KB |

The performance of Acoustic Sleeper can help the most basic of assemblies achieve 50 STC and 50 IIC requirements. Acoustic Sleepers have been been tested for STC, IIC, and is UL fire rated in multiple assemblies.

*All test results shown in this table were achieved through third party testing from accredited laboratories. The full test is available upon request.

| Independent Sound Test Results | ||||

|---|---|---|---|---|

| Type | Assembly | STC | IIC | ΔIIC |

| Concrete Structure | Bare 6" concrete slab, no ceiling or floor | - | 27 | - |

| Concrete Structure | Bare 6" concerete slab, no ceiling, Acoustic Sleeper attached to 3/4" OSB | - | 51 | 23 |

| Concrete Structure | Bare 6" concerete slab, no ceiling, Acoustic Sleeper attached to 3/4" OSB, 2mm Luxury Vinyl Tile glued directly | 52 | 51 | 23 |

| Wood Structure | Open web trusses, resilient channel and 5/8" drywall on ceiling, insulation between joists, 1/2" OSB sub-floor | 54 | 47 | - |

| Wood Structure | Open web trusses, resilient channel and 5/8" drywall on ceiling, insulation between joists, 1/2" OSB sub-floor with Acoustic Sleeper attached to 3/4" OSB | 59 | 52 | - |

| Wood Structure | Open web trusses, resilient channel and 5/8" drywall on ceiling, insulation between joists, 1/2" OSB sub-floor with Acoustic Sleeper attached to 3/4" OSB, 2mm Luxury Vinyl Tile glued directly on top | 59 | 52 | - |

Additional test results are available in this chart made by the manufacturer. All tests listed are based on IIC tests for simple ceiling assemblies with or without the sleeper system. The performance gains by incorporating the Acoustic Sleeper are significant in both wood and concrete structures with all types of finish floors.

![]()